Preventive Maintenance

Hydraulic City provides preventive maintenance service, through periodic visits by qualified engineers and technicians and using the latest diagnostic devices in order to avoid breakdowns and sudden malfunctions of production lines and equipment, by addressing any deficiencies before they reach a state of failure.

Training

Hydraulic City holds training courses in the field of hydraulic and pneumatic technology through specialized engineers and external expertise that allow the trainee to obtain diverse information and skills in this field.

Installations and Commissioning

Hydraulic City provides product installation services (fenders, arms, bumpers, platforms, etc.) at customer sites according to approved technical principles. Whether it is manufactured by Hydraulic City or provided by the customer. In addition to this, employment and on-the-job training are included.

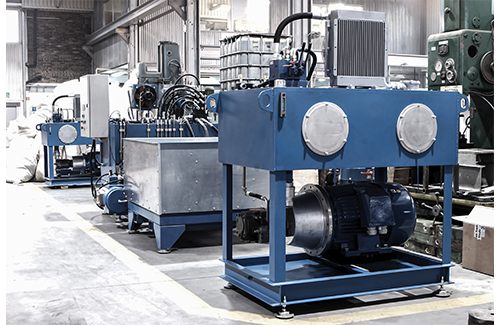

Manufacturing

In this section, Hydraulic City seeks to provide ideal solutions to its customers by permanently meeting their needs by manufacturing distinctive hydraulic products (road bumpers, cranes, pistons, etc.), as Hydraulic City is considered one of the leading companies in the Middle East region in this field, while providing the best guarantees and services. After sales […]

Spare Parts

Hydraulic City provides a wide choice of spare parts for hydraulic systems and products in addition to pneumatic systems and products through exclusive agencies for the most important international companies.

Maintenance

There are specialized workshops for all departments in the Hydraulic City under the supervision of highly qualified and experienced engineers and technicians. The maintenance departments also took into account the presence of the latest and most accurate devices to identify and maintain faults, then examine them and ensure their quality.

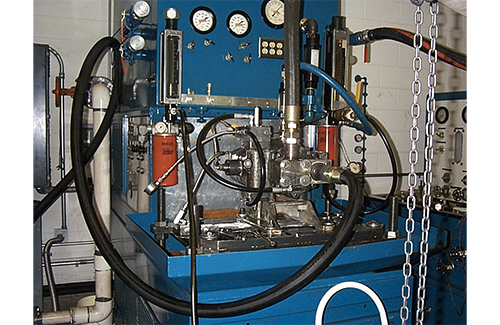

Inspection

Sections have been prepared to inspect hydraulic products manufactured or on which maintenance work has been performed, such as pumps, hydraulic and pneumatic cylinders, valves, and hydraulic units, to ensure the safety of the products’ performance and their compliance with the required performance standards.

Assembly

There is also a line to assemble products according to an advanced production process, in which the best types of spare parts and replaceable parts are used, along with the use of the latest devices to inspect the final product and ensure that it works as required.